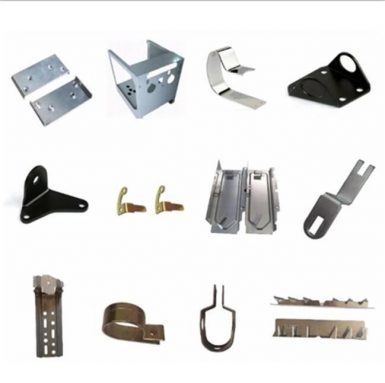

Stamping&Welding Parts

HAIYAN BOLT is capable of making various kinds and shape of metal fabrication.

Production Ability:

– Design, Develop, Prototype, and Produce with customer drawing, sample, idea.

– OEM,ODM

– Stamping/bending, Machining, Welding, Assembly.

– Samples available before mass production

Products applied in:

Construction & Decoration

Agriculture & Farming

Electricals & Telecom

Industry & Equipment

Household & Appliance

Sports & Accessories

Auto Parts

PRODUCTION CAPACITY

a) Stamping: 16Ton-500Ton

b) Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.

c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).

d). Surface treatment: Galvanizing, Anodized, Zinc/nickel/chrome/tin plating, Powder coating, Painting, etc

| Item Name | Metal Stamping and Welding Parts |

| Capacity | Stamping, Welding, Machining, and assembly. |

| Design | software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Material | Iron, Aluminum, Carbon Steel, Brass, Stainless steel etc. |

| Surface Treatment | Anodize, Chromate, Electrolytic Plating, Nickel Plating, Tin Plating, Galvanize, Tempered, Paint, Powder Coating, Polish etc. |

| Tolerance | Stamping 0.01-0.1mm, Machining 0.002-0.1mm |

| Application | Machinery, Electronics, Construction& Decoration, Lighting, Auto Parts, Transportation, Medical, Computer Accessories, Agriculture, Food Processing, etc. |

| Sample Lead-time | About 1-2weeks for custom samples |

Stamping part is a kind of forming processing method which uses press and die to exert external force on sheet, strip, pipe and profile to produce plastic deformation or separation, so as to obtain the required shape and size of workpiece (stamping part). Stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. The billets for stamping are mainly hot-rolled and cold-rolled steel plates and strips.

There are also a large number of stamping parts in living utensils and other products.

Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce workpieces with stiffeners, ribs, undulations or flanging which are difficult to manufacture by other methods, so as to improve their rigidity. Due to the use of precision die, the precision of workpiece can reach micron level, and the repetition precision is high, the specification is consistent, and the hole and socket, boss, etc. can be punched.

Generally, cold stamping parts are no longer machined, or only need a small amount of machining. The accuracy and surface state of hot stamping parts are lower than that of cold stamping parts, but they are still better than castings and forgings, and the machining amount is less.

Stamping is an efficient production method. By using compound die, especially multi position progressive die, multiple stamping processes can be completed on a press, realizing the full-automatic production from uncoiling, leveling, blanking to forming and finishing. It has high production efficiency, good working conditions and low production cost. Generally, it can produce hundreds of pieces per minute.

Stamping is mainly classified by process, which can be divided into separation process and forming process. The purpose of the separation process is to separate the stamping parts from the sheet along a certain contour line and ensure the quality requirements of the separation section. The surface and internal properties of sheet metal for stamping have a great influence on the quality of stamping products. It is required that the thickness of stamping materials is accurate and uniform; the surface is smooth without spot, scar, scratch or surface crack; the yield strength is uniform without obvious directionality; the uniform elongation is high; the yield ratio is low; the work hardening is low